Mastering Efficiency: How to Seamlessly Switch Cutting Modes

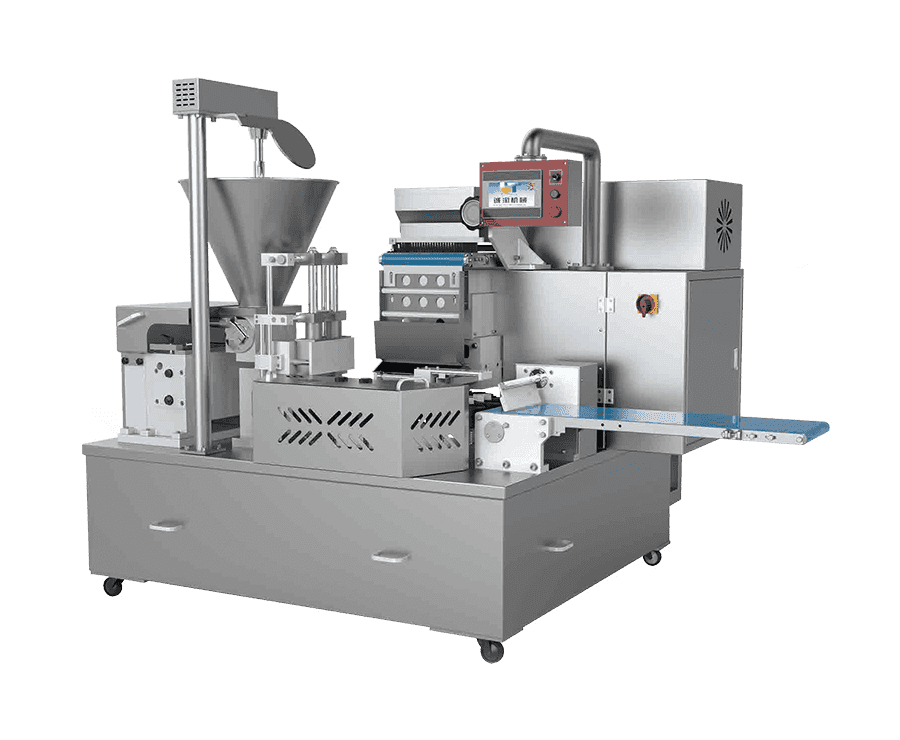

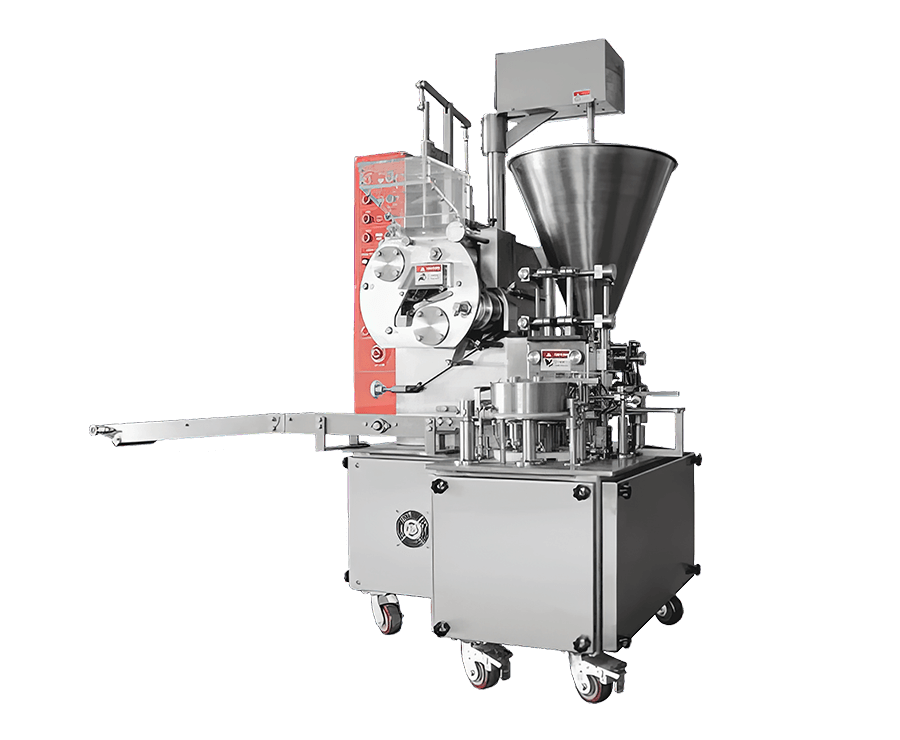

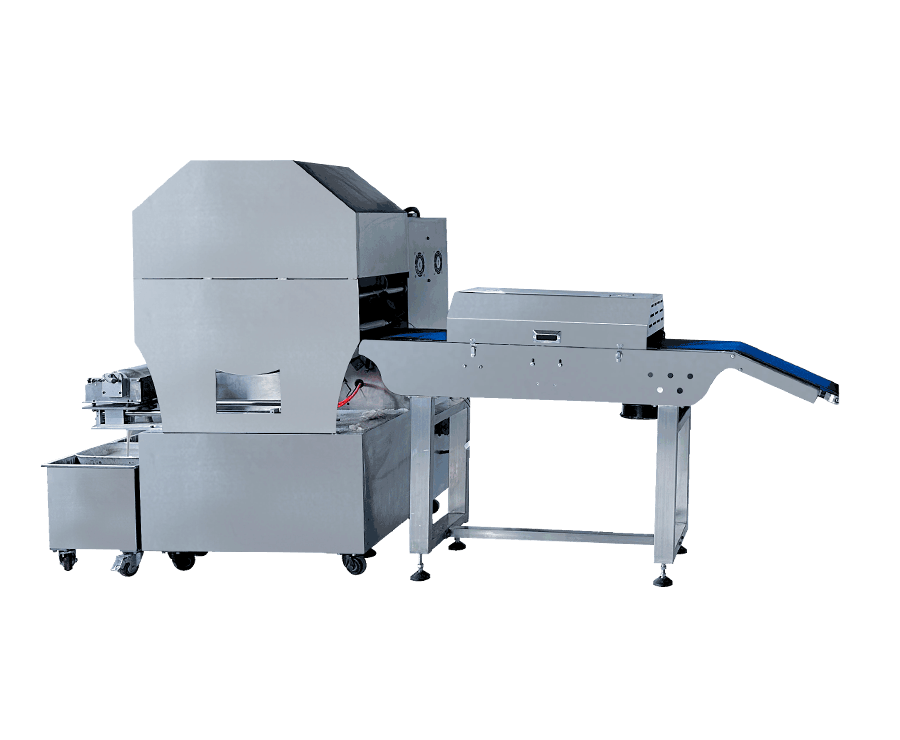

A vegetable cutting machine is a game-changer in commercial kitchens, food processing plants, and catering companies, offering unparalleled efficiency and precision. With its ability to handle a variety of fruits and vegetables—like potatoes, taro, melons, and even leafy greens like spinach or Chinese cabbage—it streamlines food preparation in ways traditional manual cutting cannot match. Beyond its impressive performance, one of the most practical concerns users often raise is how easy it is to switch between cutting modes such as slicing, dicing, and creating strips. Let’s delve into the details to highlight just how user-friendly this process is and explore the broader value of these versatile machines.

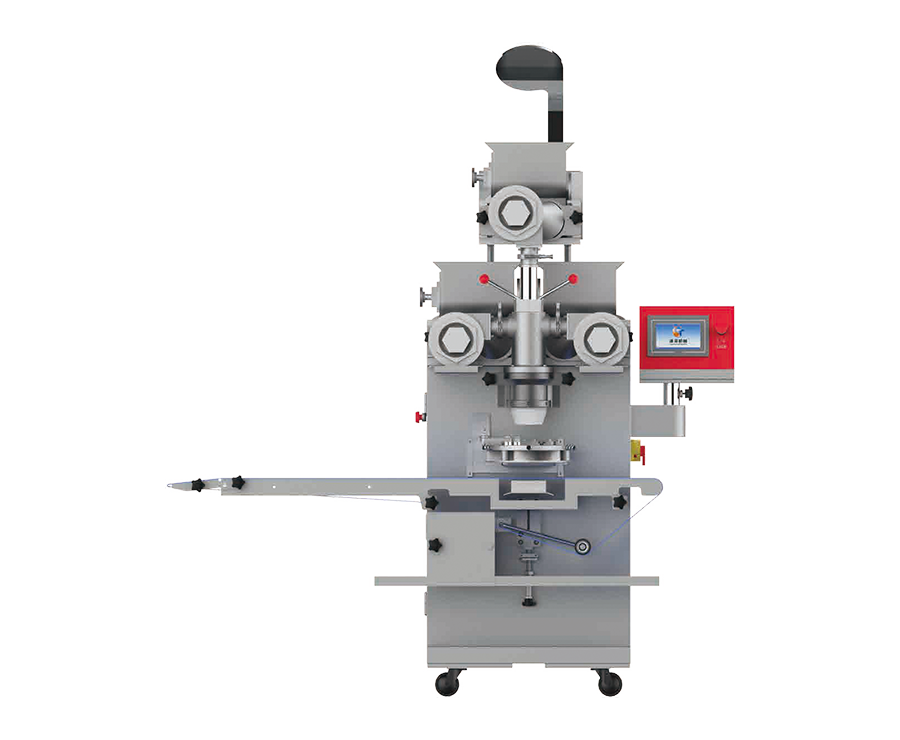

Switching between cutting modes on a professional-grade vegetable cutting machine is a breeze, thanks to its innovative design and modular cutter head system. At the heart of this convenience lies the replaceable cutter heads, each tailored for specific cuts—be it blades for slices, sickle-shaped heads for strips, or T-shaped cutters for dicing. Changing these components requires no advanced technical skills; most machines come with intuitive quick-release mechanisms or simple screws to swap out parts swiftly. This means kitchen staff can effortlessly adapt the machine to meet the demands of diverse recipes, from preparing uniform potato slices for chips to finely dicing onions for soups or stir-fries. The straightforward process minimizes downtime, which is crucial in high-pressure environments like canteens or catering services.

Adding to the ease of switching modes is the machine's integrated control system, often featuring double frequency converters. These converters allow operators to fine-tune the cutting speed and size without physically altering the machine’s settings. For instance, a slight adjustment to the converter can change the thickness of slices or the length of strips, offering flexibility that ensures every dish meets precise specifications. This electronic customization eliminates the need for constant manual intervention, enabling smooth transitions between tasks. Moreover, modern vegetable cutters often include a user-friendly interface, further simplifying adjustments with labeled controls and visual indicators, making it accessible even for those new to operating industrial kitchen equipment.

The practicality of switching cutting modes also extends to cleaning and maintenance, which are designed to be hassle-free. After changing a cutter head, users can clean it independently from the machine body, ensuring hygiene and preventing cross-contamination. The machine’s design typically incorporates stainless steel or other food-grade materials resistant to corrosion and staining, which keeps it looking and functioning like new over time. Regular maintenance, such as lubricating moving parts or checking for blade sharpness, is minimal, ensuring that the machine remains ready to tackle any cutting task.

Beyond its core functionality, the vegetable cutting machine is a marvel of safety and engineering. An automatic power-off protection feature ensures the machine won’t operate while the cutter head is being changed, protecting operators from accidents. Additionally, its compact yet robust build allows it to fit comfortably in various settings, from small school kitchens to bustling distribution centers. Coupled with its ability to handle both delicate fruits and tough vegetables without compromising shape or texture, this machine represents a vital investment for any food service professional.

The ease of switching cutting modes—paired with the machine’s efficiency, safety features, and adaptability—makes it an indispensable tool in modern food preparation. Its ability to handle diverse tasks, from slicing juicy eggplants to dicing crisp bamboo shoots, allows kitchens to maintain consistency and speed without compromising quality. Whether you’re operating a high-volume food processing plant or managing a restaurant kitchen, this machine ensures your team can keep up with demand while delivering perfectly prepped ingredients every time.

English

English Español

Español Français

Français русский

русский عربى

عربى

Contact Us