Do You Need Special Infrastructure to Run an Automatic Cake Machine?

When investing in an automatic cake machine, one of the key concerns for businesses is whether the equipment requires any special infrastructure to operate efficiently. The answer is both simple and nuanced. While these machines are designed to integrate seamlessly into most modern production facilities, certain considerations—such as power supply and water sources—play a crucial role in maximizing their performance.

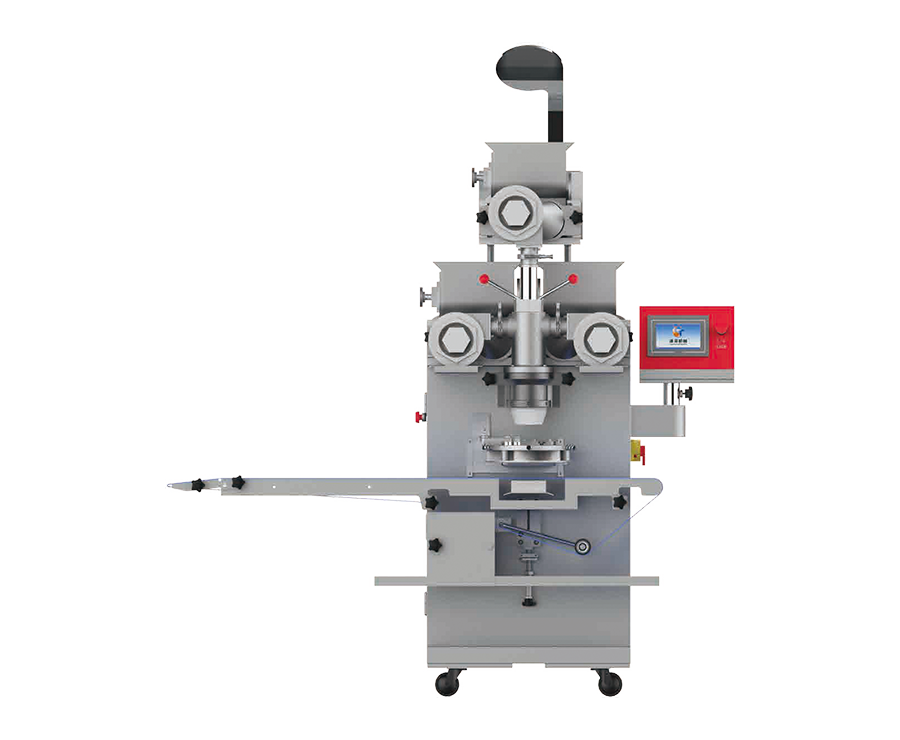

Most automatic cake machines are powered by electricity, and they typically operate on standard commercial voltage, but it’s important to ensure that the electrical infrastructure is capable of handling the machine’s specific power demands. While these machines are designed for efficiency, they can still require a significant amount of energy to maintain consistent baking temperatures and ensure precision in every cycle. Some models are equipped with energy-saving features that help reduce power consumption during off-peak production times, but businesses must still account for the overall energy usage, especially in high-volume operations. For factories or bakeries operating multiple machines simultaneously, it might be necessary to evaluate whether additional power circuits or upgrades to the existing electrical grid are required.

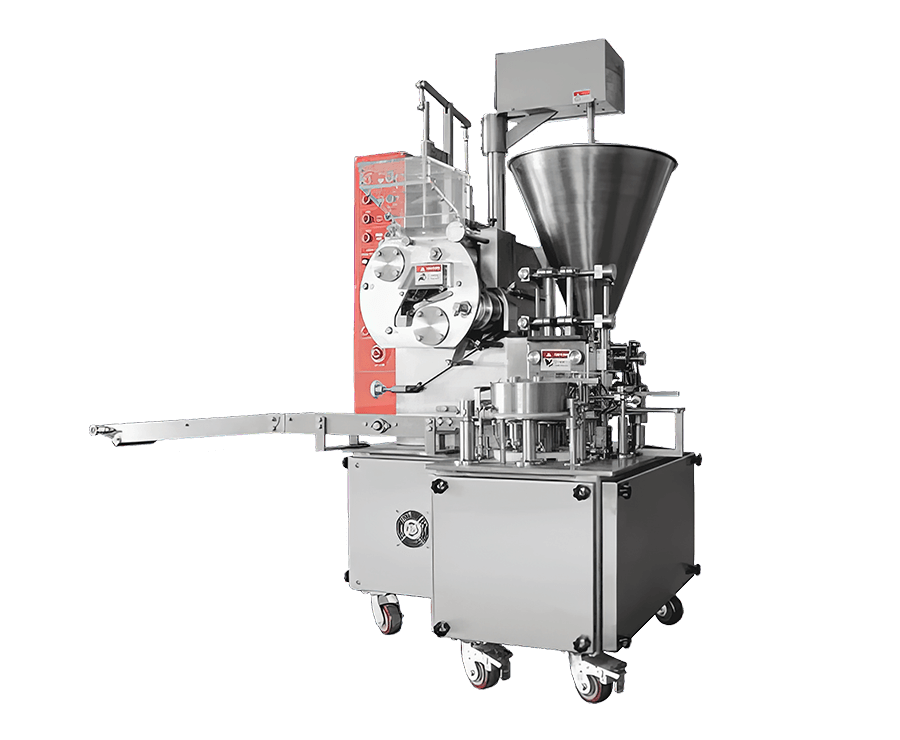

Water supply is another important consideration. Depending on the machine's design, some models may require a direct water connection, particularly if the process involves automatic cooling or humidifying components during the cake production cycle. Machines designed for high-precision tasks, like filling or frosting, may also use water for cleaning or for maintaining certain parts of the equipment. However, not all automatic cake machines require water input, so it’s essential to review the technical specifications of the specific model you're considering. If water is needed, it’s best to ensure your facility has a reliable source of clean, consistent water pressure, which can prevent disruptions and ensure smooth operations.

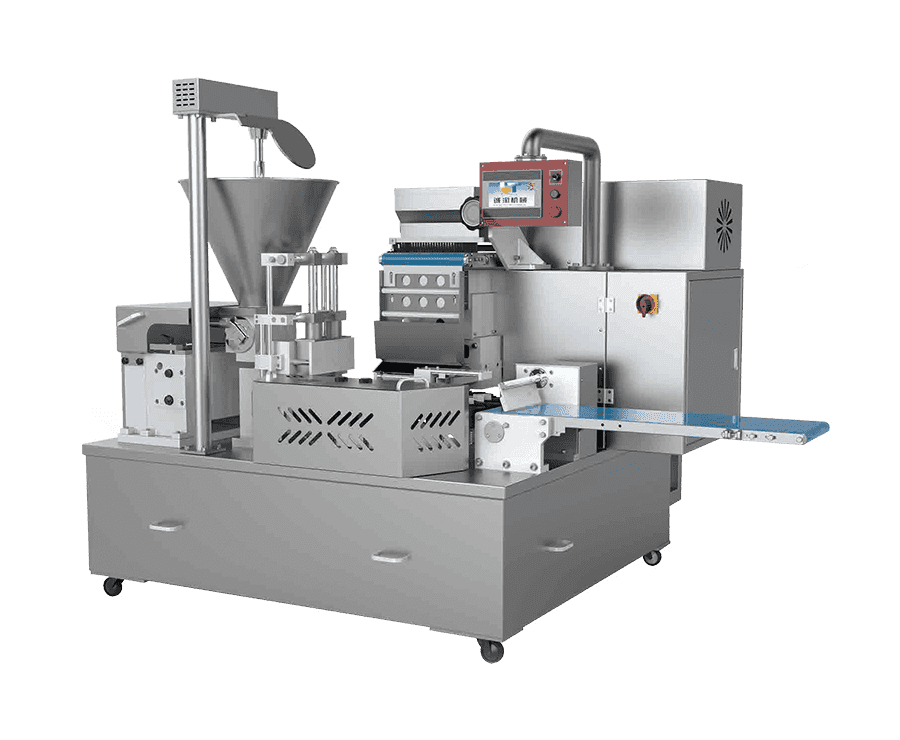

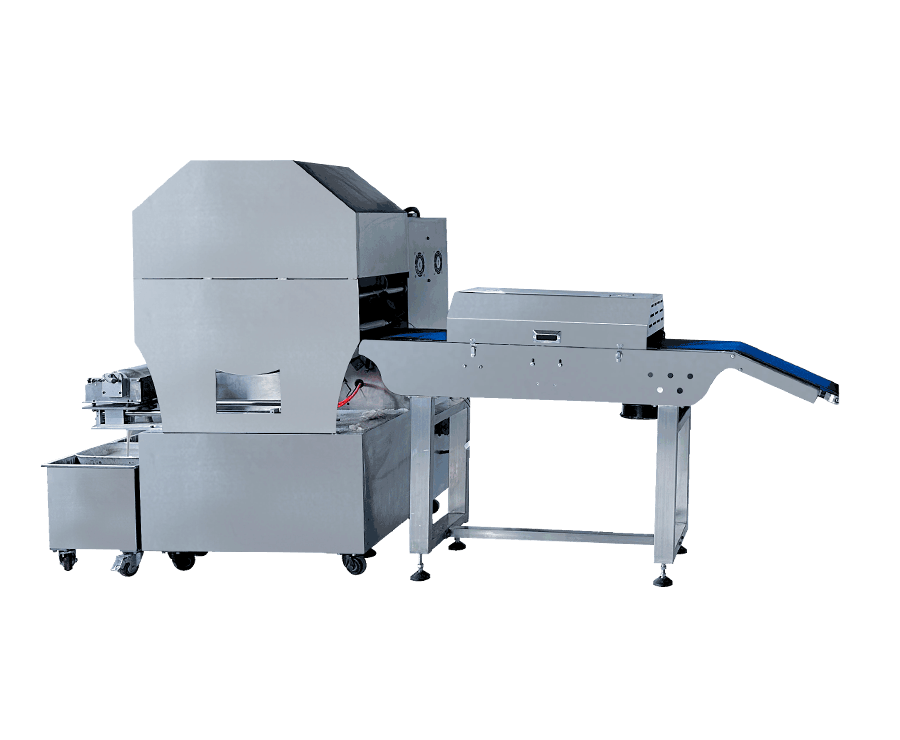

Moreover, many automatic cake machines integrate with existing production lines, so the infrastructure required is often minimal. The machines are designed to fit within existing workflows without requiring massive reconfigurations. However, if your production line is in the early stages of design or needs an upgrade, it’s worth factoring in the space requirements for the machine, any necessary modifications to plumbing or electrical systems, and ensuring proper ventilation to handle heat generated during baking.

While automatic cake machines do not generally require specialized infrastructure beyond standard power and water supplies, it’s important to assess the specific needs of your chosen model. Understanding the power and water requirements, as well as how the machine will fit into your existing production setup, can help ensure that it operates efficiently and seamlessly in your bakery or factory, boosting your productivity and quality without unnecessary operational challenges.

English

English Español

Español Français

Français русский

русский عربى

عربى

Contact Us